Pengaruh Dosis Serum Lateks terhadap Koagulasi Lateks (Hevea brasiliensis)

DOI:

https://doi.org/10.25181/aip.v4i1.36Abstract

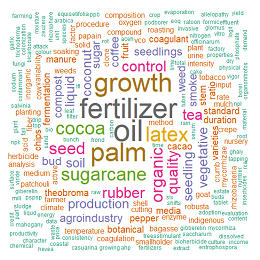

Waste water that comes out of the milling process latex factory so many and has not been utilized, often becomes a problem for the environment if the handling is not optimal. This wastewater is known as latex serum. Latex serum can be used as an alternative coagulant because it has a low pH and containing metal ions. Low pH will lower the pH of the latex to the isoelectric point and cations of alkali metals will reduce electro kinetic potential latex, so latex becomes frozen. Research purposes to determine the length of time coagulation of latex, yield of coagulum and yield dry rubber. Research conducted at the Laboratory of Plant Production at Politeknik Negeri Lampung. The material used are latex serum and latex and other materials. The equipment used is the coagulation bath, digital pH meter, a wooden spatula, milling, stopwatch, and other analysis tools. The research tested in completely randomized design with one independent variable used is composed of coagulant doses: 0%, 4%, 8%, 12%, 16% and 20% v/v and replicated 3 times. The observation are pH of latex serum, pH oflatex, coagulation time, and yield dry rubber. The result showed that for pH of latex serum is 4.9, pH of latex is 6.22, the best doses to coagulation is 20% with time to coagulation 17 minute time, coagulum yield of 59.83 and dry rubber yield of 42.10.Keywords: coagulant, latex coagulation, latex serumPermalink:Â http://jurnal.polinela.ac.id/index.php/AIP/article/view/36Downloads

References

Ali, F., S. Arta, dan F. Ahmad. 2010. Koagulasi lateks dengan ekstrak gadung (Dioscorea hispida Dennts). Jurnal Teknik Kimia 17(3): 8-16.

Ali, F., W. N, Astuti, dan N. Chairani. 2015. Pengaruh volume koagulan, waktu kontak dan temperatur pada koagulasi lateks dari kayu karet dan kulit kayu karet. Jurnal Teknik Kimia 21(3): 27-35.

Leoli, S., I. Magdalena, dan F. Ali. 2013. Pengaruh asam askorbat dari ekstrak nanas terhadap koagulasi lateks (studi pengaruh volume dan waktu pencampuran). Jurnal Teknik Kimia 19(2): 49-58.

Peiris, S. 2000. Experiennce of Cleaner Production Implementation in Rubber Industry and Potential for Future in Sri Langka. CP Association of Sri Lanka.

Sucahyo, L. 2010. Kajian Pemanfaatan Asap Cair Tempurung Kelapa Sebagai Bahan Koagulasi Lateks Dalam Pengolahan Ribbed Smoked Sheet (RSS) dan Pengurangan Bau Busuk Bahan Olah Karet. Skripsi. Institut Pertanian Bogor. Bogor.

Sulasri, M. B. Malino, dan B. P. Lapanporo. 2014. Penentuan kadar kering karet (K3) dan pengukuran konstanta dielektrik lateks menggunakan arus bolak balik berfrekuensi tinggi. Jurnal Prisma Fisika 2(1): 11–14.

Zuhrah, C. F. 2006. Karet. Karya Tulis Ilmiah. Departemen Kimia Fakultas Matematika dan Ilmu Pengetahuan Alam. Universitas Sumatera Utara. Medan.

Downloads

Published

How to Cite

Issue

Section

License

Authors who publish with Jurnal Agro Industri Perkebunan agree to the following terms:

Authors retain copyright and grant the Jurnal Agro Industri Perkebunan right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share (copy and redistribute the material in any medium or format) and adapt (remix, transform, and build upon the material for any purpose, even commercially) with an acknowledgment of the work's authorship and initial publication in Jurnal Agro Industri Perkebunan.

Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in Jurnal Agro Industri Perkebunan. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.