Penggunaan Asap Cair dan Arang Aktif Tempurung Kelapa pada Mutu Karet Krep

DOI:

https://doi.org/10.25181/aip.v3i1.14Abstract

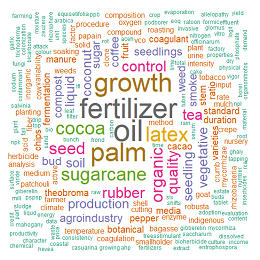

Rubber (Hevea brasiliensis Muell. Arg.) is one of important agriculture comodity on Indonesia. Wide area of Indonesia rubber agriculture on 2013 are 3,5 million hectares. With 3,2 million tones production maked Indonesia at second level ocupasi because low quality of block rubber. This research objective are getting liquid smoke dosage and active carbon as latexs coagulant. Research used randomized completely block design (RCBD) with 12 treatments and repeat 3 times. Liquid smoke dosage with 1:1 dilution and 2,60 pH are 6%, 8%, 10% and active carbon dosage 1% and 2% with formiat acid as a control. Latek coagulating process rubber production and rubber crepe quality testing suitable with SIR did in procesing factory and SIR quality testing laboratory Way Berulu PTPN VII, Pesawaran, Lampung. This research carried out November 2014 until January 2015. The results of this research showed more high liquid smoke dosage and active carbon from coconut shell can effect time of lateks coagulation fasier in 4,8 minutes. More high dosage of liquid smoke and active carbon treatment effected decrease of PRI and increase of latex waste level, dust level and evaporate substance level. Liquid smoke with 1:1 dilition and active carbon from coconut shell as latex coagulant showed dust level higher, so the latex are not suitable with SIR. The higher value because tar composition of liquid smoke from coconut shell.Keywords: active carbon coconut shell, liquid smoke, rubber crepe qualityPermalink: http://jurnal.polinela.ac.id/index.php/AIP/article/view/14Downloads

References

BPTP Jambi. 2010. Teknologi Pembekuan Lateks dengan Daerub. Leaflet. Balai Penelitian Pengkajian Teknologi Pertanian Provinsi Jambi. 2 hlm.

Darmaji, P. 1996. Kadar benzopyren produk-produk asapan tradisional. Prosiding Seminar Nasional Makanan Tradisional. Hotel Jayakarta, Yogyakarta.

Harahap, H. 2008. Pengaruh pengisi CaCo3 dan temperatur vulkanisasi terhadap sifat-sifat mekanikal film lateks karet. Jurnal Penelitian Rekayasa 1(2): 43-46.

Pasaribu, O. S. 2008. Analisis Kadar Kotoran (Dirt Content) dan Kadar Abu (Ash Content) pada Karet Remah SIR 20 PT Bridgestone Sumatera Rubber Estate, Tbk. Dolok Menangir-Serbelawan. http://respository.usus.ac.id/bitstream/123456789/13936/1/09E00103.pdf. [Diakses 23 November 2013].

Solichin, M. dan A. Anwar. 2006. Daerub K Pembeku Lateks dan Pencegah Timbulnya Bau Busuk Karet. Tabloid Sinar Tani. Jakarta.

Tahir, I. 1992. Pengambilan asap cair secara destilasi kering pada proses pembuatan karbon aktif dari tempurung kelapa. http://word-to-pdf.abdio.com. [Diakses 17 September 2013].

Triwijoso, S.U. dan Oerip Siswantoro. 1989. Pedoman teknis pengawetan dan pembekuan lateks Hevea. Balai Penelitian Perkebunan Bogor. Bogor. http://jtpunmul.files.wordpress,com/2011/06/jtp-vol4-3.pdf. [Diunduh 17 April 2013].

Wahyudi, F. 2008. Pengaruh kombinasi bahan olah karet terhadap tingkat konsistensi Plastisitas Retention Index (PRI) Karet Remah SIR 20 di PT Bridgestone Sumatera Rubber Estate Dolok Menangir. http://repository.usu.ac.id/bitstream/123456789/…/09E00092.pdf. [Diunduh 10 Desember 2013].

Wulandari, Ratna, P. Darmajdi, dan U. Santoso. 1999. Sifat antioksidan asap cair hasil redestilasi selama penyimpanan. Prosiding Seminar. Nasional Pangan Yogyakarta. 14 September 1999.

Downloads

Published

How to Cite

Issue

Section

License

Authors who publish with Jurnal Agro Industri Perkebunan agree to the following terms:

Authors retain copyright and grant the Jurnal Agro Industri Perkebunan right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share (copy and redistribute the material in any medium or format) and adapt (remix, transform, and build upon the material for any purpose, even commercially) with an acknowledgment of the work's authorship and initial publication in Jurnal Agro Industri Perkebunan.

Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in Jurnal Agro Industri Perkebunan. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.