Pengaruh Kesegaran Tebu (Saccharum officinarum L.) pada Kualitas Gula Cetak Merah

DOI:

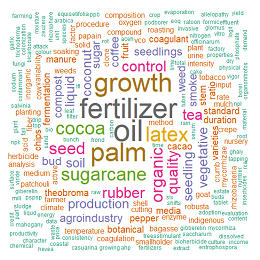

https://doi.org/10.25181/jaip.v12i1.3384Keywords:

freshness, molded brown sugar, purity, reducing sugarAbstract

To maintain sugarcane freshness, it is crucial to process it promptly after harvest. This study aims to analyze the quality of molded brown sugar derived from raw materials with varying levels of freshness. The research adopts a non-factorial design involving three main treatments: the duration of stay on the first, second, and third days, with three replications. Parameters observed during the molded brown sugar production process include brix, pol, purity, and reducing sugar from raw juice; brix, pol, purity, and reducing sugar from clear juice; color, brix, moisture content, and reducing sugar of sugar. Data analysis is performed using analysis of variance (ANOVA) with the application of Duncan's multiple range test. The purity value in raw juice data H1 with a value of 89.54 significantly differs from data H3 with a value of 73.83. Similarly, reducing sugar in raw juice H1 at 0.74 significantly differs from H3 at 0.93. The purity value in clear juice H1 at 88.34 significantly differs from H3 at 75.40. As for reducing sugar in clear juice, H1 at 0.81 is significantly smaller than H3 at 1.18. Regarding the difference between open-pan and close-pan cooking treatments, it is concluded that the cooking system producing the best molded brown sugar is the close-pan system, evident in both color results and the reduced sugar content of molded brown sugar. The best color for molded brown sugar is found in treatment H1 (day 1) with the close-pan system at 551.40. The lowest reducing sugar content is observed in treatment H1 (day 1) with the close-pan system at 0.94.Downloads

References

Akram, S. R., Sunarti, T. C., & Meryandini, A. (2019). Karakteristik isolat bakteri penghasil dekstran dari batang tebu (Saccharum officinarum L.). Jurnal Ilmu Pertanian Indonesia (JIPI), 24(2), 160–167. https://doi.org/10.18343/jipi.24.2.160

Antika, L., Siwi, P., & Ingesti, V. R. (2020). Analisis lama waktu pangkal batang tebu (Saccharum officinarum L.) tertinggal di lahan terhadap nilai rendemen. Vigor: Jurnal Ilmu Pertanian Tropika dan Subtropika, 5(1), 19-23.

Bantacut, T. (2013). Pengembangan pabrik gula mini untuk mencapai swasembada gula. Jurnal Pangan, 22(4), 299-316.

Endrizal, & Meilin, A. (2022). Prospek dan pengelolaan tanaman tebu “Poj 2878 Agribun Kerinci” sebagai penghasil gula merah di Kabupaten Kerinci, Provinsi Jambi. Ilmiah Ilmu Terapan Universitas Jambi, 6(2), 212–228.

Gandana, S. G., Ananta, &Timbul. (1974). Penuntun Pengawasan Pabrikasi (d/h bulletin No. 11), BP3GI Pasuruan.

Hartanto, E. S. (2014). Peningkatan mutu produk gula kristal putih melalui teknologi defekasi remelt karbonatasi. Jurnal Standarisasi, 16(3), 215-222.

Hegazi, S., Bukhari, M. M., El Khaseh, S., Osman, A., Eldeen, S., & Hegazi, F. (2015). Investigations of the influence of dextran on sugar cane quality and sugarcane processing in kenana sugar factory Investigations of the influence of dextran on sugar cane quality and sugar cane processing in Kenana sugar factory. Journal of Chemical and Pharmaceutical Research, 7(4), 381–392. https://www.researchgate.net/publication/301633455

ICUMSA Method GS5-1. (2022). The Determination of Sugar Solution Colour at pH 7.0. ISBN: 978-3-87040-661-5.

ICUMSA Method GS2/3-9. (2022). Sucrose, Dry Substance and Fiber in Cane and Bagasse by VIS-Polarimetry after Clarification of the Aqueous Extract with Lead Acetate and by Refractometry. ISBN: 978-3-87040-661-5.

Irundu, D., Khoiriyah, M., & Ramli, M. A. (2022). Efektivitas pembuatan gula semut menggunakan metode konvensional dan modern. Jurnal Penelitian Kehutanan BONITA, 4(1), 30-37.

Jamal, J. (2023). Palm sugar production and marketing assistance in duampanuae village, bulupoddo district. Dinamisia : Jurnal Pengabdian Kepada Masyarakat, 7(1). https://doi.org/10.31849/dinamisia.v7i1.10438

Ledheng, L., & Naisumu, Y. G. (2020). Peningkatan mutu pengolahan nira lontar menjadi gula merah cetak. Jurnal Pengabdian Masyarakat, 3(1), 1–8.

Mamuaja, C. F. (2016). Pengawasan Mutu dan Keamanan Pangan. Unsrat Press. ISBN: 978-979-3660-48-6.

Mursiti, Sailah, I., Marimin, Romli, M., & Denni, A. (2021). Strategi pengembangan sumber daya manusia yang berdaya saing dan berkelanjutan pada agroindustri tebu: Tinjauan literatur dan agenda penelitian mendatang. Jurnal Teknologi Industri Pertanian, 31(2), 129–142. https://doi.org/10.24961/j.tek.ind.pert.2021.31.2.129

Ong, R. (2023). Pengaruh pH terhadap turbiditi nira encer dan suhu imbibisi terhadap hasil. Chemistry, Education, and Science, 7(2), 174–181. https://doi.org/10.30743/cheds.v7i1.8133

Pratama, F., Susanto, W. H., & Purwantiningrum, I. (2015). Pembuatan gula kelapa dari nira terfermentasi alami (Kajian pengaruh konsentrasi anti inversi dan natrium metabisulfit). Jurnal Pangan dan Agroindustri, 3(4), 1272-1282.

Soejana, F. A. (2021). Pengendalian mutu proses produksi gula di PT. Perkebunan Nusantara X Pabrik Gula Gempolkrep, Mojokerto. Jurnal Teknotan, 14(2), 55. https://doi.org/10.24198/jt.vol14n2.4

Suwarno, Ratnani, R. D., & Indah Hartati. (2015). Proses pembuatan gula invert dari sukrosa dengan katalis asam sitrat, asam tartrat dan asam klorida. Momentum, 11(2), 99–103.

Wilberta, N., Sonya, N. T., & Lydia, S. H. R. (2021). Analisis kandungan gula reduksi pada gula semut dari nira aren yang dipengaruhi ph dan kadar air. Bioedukasi (Jurnal Pendidikan Biologi), 12(1), 101-108.

Winata, E. D., & Susanto, W. H. (2015). Pengaruh penambahan antiinversi dan suhu imbibisi terhadap tingkat kesegaran nira tebu. Pangan dan Agroindustri, 3(1), 271–280.

Yuwana, A. M. P., Putri, D. N., & Harini, N. (2022). Hubungan antara atribut sensori dan kualitas gula merah tebu: pengaruh pH dan kondisi karamelisasi. Teknologi Pangan: Media Informasi Dan Komunikasi Ilmiah Teknologi Pertanian, 13(1), 54–66. https://doi.org/10.35891/tp.v13i1.2767

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Ratna Sri Harjanti, Rahmi Sabrina Hamami, Anna Kusumawati, Azhari Rizal, Muhammad Mustangin, Dwi Aryani Suryaningrum, Yunaidi Yunaidi

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with Jurnal Agro Industri Perkebunan agree to the following terms:

Authors retain copyright and grant the Jurnal Agro Industri Perkebunan right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share (copy and redistribute the material in any medium or format) and adapt (remix, transform, and build upon the material for any purpose, even commercially) with an acknowledgment of the work's authorship and initial publication in Jurnal Agro Industri Perkebunan.

Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in Jurnal Agro Industri Perkebunan. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.