Pengaruh Konsentrasi NaOH dan Suhu Delignifikasi pada Kandungan Lignoselulosa Tandan Kosong Kelapa Sawit

DOI:

https://doi.org/10.25181/jaip.v12i1.2729Keywords:

delignification, fiber, oil palm empty fruit bunches, sodium hydroxideAbstract

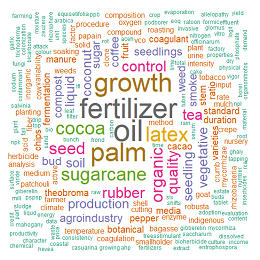

Palm oil processing in the industry produces products and waste; the waste generated from the palm oil processing process will have a negative impact on the environment if it is not processed. Oil palm empty fruit bunches are lignocellulosic solid wastes that contain cellulose, lignin, and hemicellulose content, so they have the potential to be raw materials for making bioethanol. In the process of producing bioethanol, delignification is an early stage that aims to reduce the lignin content in lignocellulosic materials with alkaline or alkaline pretreatment solutions such as the use of NaOH can be used to help separate lignin from cellulose fibers. This study aimed to analyze the effect of NaOH concentration and delignification temperature on the lignocellulosic content of oil palm empty fruit bunches. The research method was arranged descriptively with two treatments: the concentration of NaOH consisting of 3%, 4%, and 5%, and the heating temperature consisting of 100 oC, 110 oC, and 120 oC. Lignocellulosic content can be calculated using the Chesson method analysis with the Microsoft Excel 2016 application as a data processor. The results showed that 1 M NaOH concentration with heating temperature had an effect on the observations of hemicellulose, cellulose, and lignin. The best treatment of 1 M NaOH concentration and heating temperature on hemicellulose, cellulose, and lignin was produced by the treatment of 5% NaOH concentration with a heating temperature of 120 0C.Downloads

References

Darsono, & Sumarti, M. (2014). Pembuatan bioetanol dari lignoselulosa tandan kosong kelapa sawit menggunakan perlakuan awal iradiasi berkas elektron dan NaOH. Kimia Kemasan, 36, 245–252.

Herawati, D. A., & Wibawa, A. A. (2019). Pengaruh penambahan molase pada produksi bioethanol dari limbah padat industri pati aren. Jurnal Biomedika , 2(2), 198–199.

Hartari, W. R., Undadraja, B., Delvitasari, F., Maryanti, Ersan, & Sarono. (2023a). Pemanfaatan limbah delignifikasi bioethanol dari tandan kosong kelapa sawit menjadi surfaktan natrium lignosulfonat. G-Tech: Jurnal Teknologi Terapan, 7(3), 1180–1186. https://doi.org/10.33379/gtech.v7i3.2786

Hartari, W. R., Delvitasari, F., Maryanti, M., Undadraja, B., Hasbullah, F., & Deksono, G. A. (2023b). Pengujian lignoselulosa tandan kosong kelapa sawit dengan waktu delignifikasi H2SO4 menggunakan uap bertekanan. Jurnal Agro Industri Perkebunan, 11(3), 151-158. https://doi.org/10.25181/jaip.v11i3.3007

Ika, D. (2019). Alat otomatisasi pengukur kadar vitamin C dengan metode titrasi asam basa. Jurnal Neutrino, 1(2), 163–178.

Ika, K., Habibah, U., Yustiana, D., & Fajriah, I. (2017). Proses delignifikasi menggunakan NaOH dan amonia (NH3 ) pada tempurung kelapa. Jurnal Integrasi Proses, 6(4), 197–201.

Lee, S. H., Doherty, T. V., Linhardt, R. J., & Dordick, J. S. (2009). Ionic liquid mediated selective extraction of lignin from wood leading to enhanced enzymatic cellulose hydrolysis. Biotechnol. and Bioeng., 102(5), 1368-1376.

Mariana, F. L., Zulfansyah, & Iwan, M. (2010). Delignifikasi tandan kosong sawit dalam media asam formiat. Seminar Nasional Sains & Teknologi III (pp. 217–225).

Muryanto, Sudiyani, Y., & Abimanyu, H. (2016). Optimasi proses perlakuan awal NaOH tandan kosong kelapa sawit untuk menjadi bioetanol. Jurnal Kimia Terapan Indonesia, 18(1), 27-35.

Rahmatullah, R., Selpiana, S., Sari, E. O., Putri, R. W., Waluyo, U., & Andrianto, T. (2020). Pengaruh konsentrasi NaOH terhadap kadar selulosa pada proses delignifikasi dari serat kapuk sebagai bahan baku biodegradable plastic berbasis selulosa asetat. Applicable Innovation of Engineering and Science Research (AVoER), 12(8), 305–308.

Sari, P. D., Puri, W. A., & Hanum, D. (2019). Delignifikasi Bahan Lignoselulosa: Pemanfaatan Limbah Pertanian. CV Penerbit Qiara Media.

Siagian, H. S. (2019). Modifikasi Alang-alang Sebagai Filler Adsorben Logam Berat. Deepublish.

Susilawati, & Supijatno. (2015). Pengelolaan limbah kelapa sawit (Elaeis guineensis Jacq.) di perkebunan kelapa sawit, riau waste. Bul. Agrohorti, 3(2), 32-37.

Sutikno, Marniza, M, & Yanti, M. F. (2015). Pengaruh perlakuan awal basa dan asam terhadap kadar gula reduksi tandan kosong kelapa sawit. Jurnal Teknologi Industri & Hasil Pertanian, 20(1), 1–10.

Sutiya, B., Istikowati, W. T., & Rahmadi, A. (2012). Kandungan kimia dan sifat serat alang-alang (Imperata cylindrica) sebagai gambaran bahan baku pulp dan kertas. Bioscientiae, 9(2), 8–19.

Yoricya, G., Aisyah, S., Dalimunthe, P., Manurung, R., & Bangun, N. (2020). Hidrolisis hasil delignifikasi tandan kosong kelapa sawit dalam sistem cairan ionik choline chloride. Jurnal Teknik Kimia USU, 5(1), 27–33.

Yuanita, E., Gunawan, E. R., Kurniawati, L., & Kamali, S. R. (2013). Studi kinetika reaksi esterifikasi enzimatis asam miristat dengan oleil alkohol. Molekul, 8(1), 9-19.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Hafid Andre Permana, Febrina Delvitasari, Widia Rini Hartari, Maryanti Maryanti

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with Jurnal Agro Industri Perkebunan agree to the following terms:

Authors retain copyright and grant the Jurnal Agro Industri Perkebunan right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share (copy and redistribute the material in any medium or format) and adapt (remix, transform, and build upon the material for any purpose, even commercially) with an acknowledgment of the work's authorship and initial publication in Jurnal Agro Industri Perkebunan.

Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in Jurnal Agro Industri Perkebunan. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.