Pengujian Lignoselulosa Tandan Kosong Kelapa Sawit dengan Waktu Delignifikasi H2SO4 Menggunakan Uap Bertekanan

DOI:

https://doi.org/10.25181/jaip.v11i3.3007Keywords:

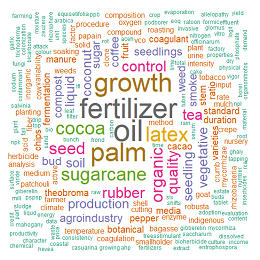

delignification, lignin, lignocellulosic, oil palm empty fruit bunchesAbstract

Oil palm empty fruit bunches (EFB) are the most abundant solid waste from the palm oil industry and are underutilized, even though they have the potential to become industrial raw materials because they contain three fractions, namely cellulose, hemicellulose, and lignin. This research was carried out using the steam method using 1 molar sulfuric acid with concentrations of 6.4%, 7.6%, and 8.7%. The delignification temperature was measured at 120 oC and with different delignification times of 60 minutes, 90 minutes, and 120 minutes. The best treatment with 1 M H2SO4 concentration and heating time for hemicellulose was the treatment with 8.7% H2SO4 concentration and 90 minutes of heating time. The best treatment with 1 M H2SO4 concentration and heating temperature for cellulose was found to be 6.4% H2SO4 concentration with 90 minutes of heating time. The best treatment with a 1 M H2SO4 concentration and heating temperature for lignin was the 6.4% H2SO4 treatment with 90 minutes of heating time.Downloads

References

Badan Standarisasi Nasional Indonesia. (2009). Pulp-Cara Uji Kadar Selulosa Alfa, Beta, dan Gamma. In SNI 0444.

Dewanti, D. P. (2018). Potensi selulosa dari limbah tandan kosong kelapa sawit untuk bahan baku bioplastik ramah lingkungan. Jurnal Teknologi Lingkungan, 19(1), 81-88. https://doi.org/10.29122/jtl.v19i1.2644

Ditjen Perkebunan. (2017). Prospek Perkebunan dan Industri Minyak Kelapa Sawit di Indonesia. PT Bisinfocus Kelapa Sawit.

Hartari, W. R., Delvitasari, F., Sarono, & Undadraja, B. (2021). Delignification of oil palm empty bunch with compressive heat and naoh concentration in separate lignosellulose. IOP Conference Series: Earth and Environmental Science, 1012(1). https://doi.org/10.1088/1755-1315/1012/1/012056

Haryanti, A., Norsamsi, N., Fanny Sholiha, P. S., & Putri, N. P. (2014). Studi pemanfaatan limbah padat kelapa sawit. Konversi, 3(2), 20. https://doi.org/10.20527/k.v3i2.161

Juanda, Irfan, & Nurdiana. (2011). Pengaruh metode dan lama fermentasi terhadap mutu MoL (mikroorganisme lokal). J. Floratek, 5(6), 140–143.

Kahfi, S. A. (2019). Delignifikasi Biomassa Lignoselulosa Menggunakan Enzim Dari Larva Cossus-Cossus Dalam Produksi Biofuel Generasi Kedua [Unpublished undergraduate thesis]. Universitas Islam Negeri Alauddin.

Manalu, H. V., Wibisono, Y., & Indriani, D. W. (2020). Hidrolisis hemiselulosa pada kulit pisang ambon hong (Musa acuminata) menggunakan katalis asam sulfat (H2SO4) pada produksi xilosa. Jurnal Keteknikan Pertanian Tropis dan Biosistem, 8(1), 46–56. https://doi.org/10.21776/ub.jkptb.2020.008.01.05

Purba, J. H. V., & Sipayung, T. (2017). Perkebunan kelapa sawit indonesia dalam perspektif pembangunan berkelanjutan. Jurnal Masyarakat Indonesia, 43(1), 81-94.

Rachim, P. (2012). Pembuatan surfaktan natrium lignosulfonat dari tandan kosong kelapa sawit dengan sulfonasi langsung. Jurnal Teknik Kimia, 18(1), 41–46.

Rilek, N. M., Hidayat, N., & Sugiarto, Y. (2017). Hidrolisis lignoselulosa hasil pretreatment pelepah sawit (Elaeis guineensis Jacq.) menggunakan H2SO4 pada produksi bioetanol. Industria: Jurnal Teknologi dan Manajemen Agroindustri, 6(2), 76–82. https://doi.org/10.21776/ub.industria.2017.006.02.3

Rodiansono, R., Utami, U. B. L., Widyastuti, N., Wulandari, P. C., & Risnawati, I. (2016). Hidrolisis lignoselulosa dari tandan kosong kelapa sawit menggunakan katalis asam karboksilat. Jurnal Ilmiah Berkala Sains dan Terapan Kimia, 7(1), 60–71.

Santoso, S. (2010). Palm Oil Boom in Indonesia: From Plantation to Downstream Products and Biodiesel, Clean (Vol. 36, Issue 5).

Saputra, B. Y. E., Fahmi, M. F., & Widjaja, T. (2022). Fraksinasi lignoselulosa dari TKKS dengan metode steam explosion pretreatment disertai penambahan asam formiat. Jurnal Teknik ITS, 11(2), 67-72. https://doi.org/10.12962/j23373539.v11i2.89395

Sari, R. M. (2016). Optimasi Produksi Bioetanol dari Tandan Kosong Kelapa Sawit Menggunakan Metode Sakarifikasi dan Fermentasi Serentak [Unpublished undergraduate thesis]. Universitas Lampung.

Sukowati, A., Sutikno, & Rizal, S. (2014). Produksi bioetanol dari kulit pisang melalui hidrolisis asam sulfat. Jurnal Teknologi dan Industri Hasil Pertanian, 19(3), 274–288.

Susilo, B., Agustiningrum, D. A., & Indriani, D. W. (2017). Pengaruh Penyimpanan atmosfer termodifikasi (modified atmosphere storage/MAS) terhadap karakteristik jamur tiram putih (Pleurotus ostreatus). Agritech, 36(4), 369. https://doi.org/10.22146/agritech.16758

Yoricya, G., Dalimunthe, S. A. P., Manurung, R., & Bangun, N. (2016). Hidrolisis hasil delignifikasi tandan kosong kelapa sawit dalam sistem cairan ionik choline chloride. Jurnal Teknik Kimia USU, 5(1), 27–33.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Widia Rini Hartari, Febrina Delvitasari, Maryanti Maryanti, Bigi Undadraja, Fizzaria Hasbullah, Giannis Aji Deksono

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with Jurnal Agro Industri Perkebunan agree to the following terms:

Authors retain copyright and grant the Jurnal Agro Industri Perkebunan right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share (copy and redistribute the material in any medium or format) and adapt (remix, transform, and build upon the material for any purpose, even commercially) with an acknowledgment of the work's authorship and initial publication in Jurnal Agro Industri Perkebunan.

Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in Jurnal Agro Industri Perkebunan. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.