Pengaturan Dosis Asap Cair Berbahan Baku Tempurung Kelapa Sebagai Bahan Penggumpal Lateks

DOI:

https://doi.org/10.25181/jaip.v6i2.791Abstract

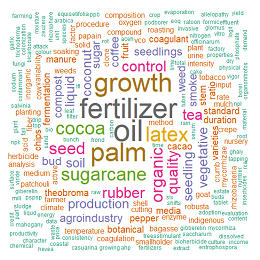

In the processing of solid rubber, such as the manufacture of crumb rubber and rubber smoke sheet, one of the most important stages is the coagulation process using coagulant. The coagulation process is instrumental in determining for quality the rubber produced. Low quality of bokar is caused by farmers using coagulant which are not recommended. Because of that, it’s necessary to found the alternative coagulant that does not damage the quality and the price is relatively cheap. The purpose of this research is gets the best dosage of coconut shell liquid smoke for latex coagulation and to evaluate quality crepe rubber coagulum using coconut shell liquid smoke. The quality observed is dirt content, ash content, volatile matter, PRI, Mooney viscosity, and color index was implemented at PTPN VII, Way Berulu, Pesawaran District. The doses used were 0,1%, 1,5%, 2%, 2,5%, and 3%. The result showed that the most effective dose used in this research was 1% with quality approaching formic acid treatment. Keywords: coconut shell, formic acid, latex coagulant, liquid smokeDownloads

References

Boerhendhy, I., & Amypalupy, K. (2016). Optimalisasi produktivitas karet melalui penggunaan bahan tanam, pemeliharaan, sistem eksploitasi dan peremajaan tanaman. Jurnal Penelitian dan Pengembangan Pertanian, 30(1), 23-30.

Fitriyani, L., Fitriani, F., & Edison, R. (2016). Analisis Pengendalian Kualitas Produk SIR 3L di PT Perkebunan Nusantara VII Unit Usaha Way Berulu. Jurnal Agro Industri Perkebunan, 4(2), 106-117.

Martrias, D., Edison, R., & Supriyatdi, D. (2015). Penggunaan Asap Cair dan Arang Aktif Tempurung Kelapa pada Mutu Karet Krep. Jurnal Agro Industri Perkebunan, 3(1), 1-10.

Maryanti, M., & Edison, R. (2016). Pengaruh Dosis Serum Lateks terhadap Koagulasi Lateks (Hevea brasiliensis). Jurnal Agro Industri Perkebunan, 4(1), 54-59..

Simanjuntak, M., Bachtiar, B., & Rachmawan, A. (2012). Pengujian Mutu Kritex SP Sebagai Penggumpal Lateks. Jurnal Penelitian Karet, 30(2), 108-116.

Solichin, M., & Anwar, A. (2006). Deorub K Pembeku Lateks dan Pencegah Timbulnya Bau Busuk Karet. Tabloid Sinar Tani. Jakarta.

Sucahyo, L. (2010). Kajian Pemanfaatan Asap Cair Tempurung Kelapa sebagai Bahan Koagulan Lateks dalam Pengolahan Ribbed Smoked Sheet (RSS) dan Pengurang Bau Busuk Bahan Olahan Karet. Upbulished undergraduate thesis, Institut Pertanian Bogor, Bogor.

Vachlepi, A., Suwardin, D., & Purbaya, M. (2015). Karakterisasi Kondisi Penggumpalan Dan Mutu Karet Yang Digumpalkan Dengan Koagulan Deorub Formula Baru. Jurnal Penelitian Karet, 33(2), 175-182.

Yulita, E. (2012). Pengaruh asap cair serbuk kayu limbah industri terhadap mutu bokar. Journal of Industrial Research (Jurnal Riset Industri), 6(1), 13-22.

Yunus, M. (2011). Teknologi pembuatan asap cair dari tempurung kepala sebagai pengawet makanan. Jurnal Sains dan Inovasi, 7(1), 53-61.

Downloads

Published

How to Cite

Issue

Section

License

Authors who publish with Jurnal Agro Industri Perkebunan agree to the following terms:

Authors retain copyright and grant the Jurnal Agro Industri Perkebunan right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share (copy and redistribute the material in any medium or format) and adapt (remix, transform, and build upon the material for any purpose, even commercially) with an acknowledgment of the work's authorship and initial publication in Jurnal Agro Industri Perkebunan.

Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in Jurnal Agro Industri Perkebunan. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.