Pengaruh Asap Cair Berbahan Baku Pelepah Kelapa Sawit Sebagai Koagulan pada Kualitas Karet Krep

DOI:

https://doi.org/10.25181/aip.v4i1.35Abstract

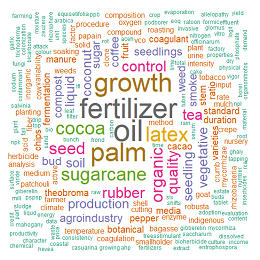

Public rubber platation Indonesia reached 80% from the vast number of rubber Indonesia. But people rubber low quality, because the use of coagulant is not advice. The researc aims to use liquid smoke from midrib plam oil as an alternative coagulants formic acid to maintain the quality of crepe rubber. Dose of liquid smoke from midrib plam oil 4, 6, 8, 10, 12, and 14% given in each treatment 250 ml latex and will be tested pH, long clotting time, dry rubber content, plasticity retention index (PRI), leves of substance evaporates, until ash, and levels of dirt in acordance with the SNI 1903 : 2000. Tests conducted in te laboratory PTPN VII business Wwy Unit Berulu, Pesawara, Lampung. The results showed a dose of liquid smoke 4 – 12% crepe rubber produce with quality SIR 10, long clottng time dose treadment liquid smoke 14% but quality is only reached SIR 20 and dose treadment liquid smoke from midrib plam oil is best dosage 8% v/v.Keywords: crepe rubber, latex coagulant, liquid smoke, oil palm frondPermalink: http://jurnal.polinela.ac.id/index.php/AIP/article/view/35Downloads

References

Abednego, J. G. 1981. Pengetahuan Lateks, Direktorat Normalisasi dan pengendalian mutu. Departemen Perdagangan dan Koperasi. Jakarta.

Direktorat Jenderal Perkebunan 2013. Peningkatan Produksi, Produktivitas dan Mutu Tanaman Tahunan. Kementerian Pertanian. Jakarta.

Direktorat Pengolahan Hasil Pertanian. 2006. Pedoman Pengolahan Limbah Industri Sawit. Departemen Pertanian. Jakarta.

Girrard, J. P. 1992. Komposisi Kandungan pada Kayu. Laporan Penelitian. Jakarta.

Hasma, H. dan Alias bin Othman. 1990. Role of some non-rubber constituents on thermal oxidative ageing of natural rubber. J. Nat. Rub. Res. 5(1): 1-8.

Oramahi, H. A., F. Diba, dan Wahdina. 2011. Aktivitas anti jamur asap cair dari serbuk gergaji kayu Akasia (Acacia mangium Willd) dan kayu Laban (Vitex pubescens Vahl). Bionatura 13(1): 79-84.

Padil dan Yelmida, 2009. Produksi Nitro Selulosa Sebagai Bahan Baku Propelan yang Berbasis Limbah Padat Sawit. Laporan Penelitian Hibah Penelitian Stranas Batch II. Universitas Riau.

Pszczola, D. E. 1995. Tour higlights production and uses of smoke base flavors. Food Technology 49(1): 70-74.

Balai Penelitian Tanaman Industri dan Penyegar (Balitri). 2014. Petani di Babel Masih Menggunakan Tawas Sebagai Koagulan Lateks. http://balittri.litbang.pertanian.go.id/index.php/component/content/article/49-infotekno/206-petani-di-babel-masih-menggunakan-tawas-sebagai-koagulan-lateks. [Diakses 2 September 2014].

Rao. 1974. Upaya Industri Karet Nasional dalam Menghadapi Persaingan Pasar Karet Remah di Dunia Internasional. http://ww.kdeitaipei.org/banner/kaet.htm. [Diakses 25 Juli 2015].

Rokhmah, H. F. 2014. Uji Pemanfaatan Limbah Cair Tahun dan Asap Cair Sebagai Bahan Koagulasi Latek. Skripsi. Program Studi PMIP. Jurusan Budidaya Tanaman Perkebunan. Politeknik Negeri Lampung. Lampung.

Solichin. 2007. Pengembangan Sistem Asap Cair dan Formulanya untuk Karet. Protipe pengeringan karet dengan energi alternatif, serta perumusan asap cair. http://elib.pdii.lipi.go.d/katalog/index.php/searchkatalog/byId/282130. [Diakses 12 September 2014].

BSN. 2000. Standar Nasional Indonesia 06-1903-2000. Standar bahan baku olah karet (Bokar).

Tahir, I. 1992. Pengambilan Asap Cair Secara Destilasi Kering pada Proses Pembuatan Karbon Aktif dari Tempurung Kelapa. Skripsi. Universitas Gadjah Mada. Yogyakarta.

Wahyudi, F. 2008. Pengaruh kombinasi bahan olahan karet terhadap tingkat konsistensi plastisitas retension index (PRI) karet remah SIR 20. PT Bridgestone sumatera Rubber Estate Dolok Menangir. File: repository.usu.ac.id/bitstream/123456789/.../09E00092.pdf. [Diakses: 26 Juli 2015].

Wikipedia. 2013. Asap Cair. http://id.wikipedia.org/wiki/Asap_cair. [Diakses 12 September 2014].

Wulandari, Ratna, P. Darmadji, dan U. Santosa. 1999. Sifat Antioksidan Asap Cair Hasil Redentilasi Selama Penyimpanan. Prosiding Seminar Nasional Pangan. Yogyakarta

Downloads

Published

How to Cite

Issue

Section

License

Authors who publish with Jurnal Agro Industri Perkebunan agree to the following terms:

Authors retain copyright and grant the Jurnal Agro Industri Perkebunan right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share (copy and redistribute the material in any medium or format) and adapt (remix, transform, and build upon the material for any purpose, even commercially) with an acknowledgment of the work's authorship and initial publication in Jurnal Agro Industri Perkebunan.

Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in Jurnal Agro Industri Perkebunan. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.