Evaluasi Kinerja Pengelolaan Pabrik Karet Remah: Studi Kasus di Sumatera Selatan

DOI:

https://doi.org/10.25181/aip.v3i2.24Abstract

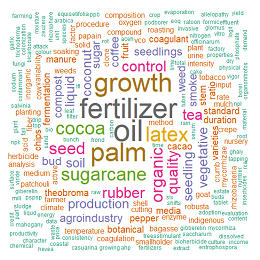

Indonesia as the world's second largest natural rubber producer, products derived predominantly (> 90%) in the form of crumb rubber. In the management of crumb rubber factoryshould basically be dynamic is to follow developments in technology and customer requirements, as well as efforts to increase competitiveness. To determine the performance of crumb rubber factory on the current and future compliance requirements have made observations on the management of crumb rubber factory. This research was conducted using a survey of crumb rubber factory in South Sumatera province. Determination respondents crumb rubber factory done intentionally (purposive sampling) the criteria for the location of the plant, production capacity, production processes, energy use, and production control. Survey activities conducted in crumb rubber factory located in Musi Banyuasin, Muara Enim and Banyuasin districts, as well as four factories located in the city of Palembang. Parameter observations include raw rubber material conditions, contamination control, energy aspects of processing, and the malodor control. The survey results indicate the selectivity in the purchase raw rubber material by the crumb rubber factories decreased due to competition tightly, it could have an impact on the risk of contamination problems in products SIR. Management of crumb rubber factories have sought to convert the use of fossil fuel resources to materials that are environmentally friendly. Tata factory work generally show has been categorized as good, there is even a plant considered to be very good, fairly intensive use of labor inspectors in some parts of the process and the results are assessed effectively. Odor problems at the crumb rubber factories can be reduced by using good air circulation room and poring Deorub into blanket before the drying.Keywords: consistency, contaminant, crumb rubber, energy, factory, quality, raw materialPermalink: http://jurnal.polinela.ac.id/index.php/AIP/article/view/24Downloads

References

Budiman, A. F. S. 1992. Kecermatan Kerja dalam Pengolahan SIR. Kursus Jaminan Mutu Terpadu Karet Indonesia. Gapkindo Cabang Sumatera Selatan. Palembang 15-18 September 1992.

Honggokusumo, S., B. Handoko dan A. Anwar. 1995. Effect of maturation and predrying on the cure rate produced from cup lump and processability of SIR 20 grade. Workshop on crumb rubber semi industrial trials. Sembawa 30 August 1995.

Santosa, A. M., dan A. Anwar. 1995. Effect of mechanical parameters in the crumb pilot plant on crumb rubber quality. Workshop on crumb rubber semi industrial trials. Sembawa 30 August 1995.

Suwardin, D. 1990. Kajian teknik pengolahan dan mutu karet remah. Buletin Perkebunan Rakyat 6(1) : 32-38.

Suwardin, D., I. Jamaran, A. Basith dan A. F. S. Budiman. 1995. Optimasi Pengendalian Mutu Produksi Karet Remah SIR 20 dengan Teknik Program Sasaran. Jurnal Penelitian Karet, 13(2): 178-194.

Suwardin, D., A. Anwar dan C. Nancy. 1997. Pengaruh jenis bokar dan tahapan proses terhadap mutu karet remah. Jurnal Penelitian Karet 15(2): 57-75.

Suwardin, D., M. Solichin dan A. Anwar. 2000. Analisis tata kerja pabrik karet remah. Jurnal Penelitian Karet 18 (1) : 1-18.

Suwardin, D. dan M. Solichin. 2000. The Establishment of Crumb Rubber Industry in Indonesia during 30 years: Techno-economics Analysis. Proc. Indonesian Rubb. Conf and IRRDB. pp.: 600-611

Tunas, E. dan A. F. S Budiman. 1992. Panduan Jaminan Mutu Terpadu : Pengolahan SIR dari bahan olah karet rakyat. Kursus Jaminan Mutu Terpadu Karet Indonesia. Gapkindo Cabang Sumatera Selatan. Palembang 15-18 September 1992.

Downloads

Published

How to Cite

Issue

Section

License

Authors who publish with Jurnal Agro Industri Perkebunan agree to the following terms:

Authors retain copyright and grant the Jurnal Agro Industri Perkebunan right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share (copy and redistribute the material in any medium or format) and adapt (remix, transform, and build upon the material for any purpose, even commercially) with an acknowledgment of the work's authorship and initial publication in Jurnal Agro Industri Perkebunan.

Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in Jurnal Agro Industri Perkebunan. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.