Inovasi Biopolybag Ramah Lingkungan dari Tandan Kosong Kelapa Sawit Diperkuat dengan Bahan Isian Sekam Padi

DOI:

https://doi.org/10.25181/jaip.v10i1.2221Keywords:

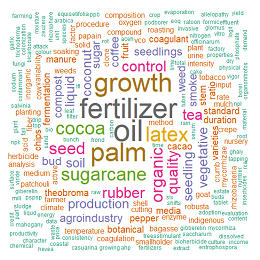

biopolybag, empty fruit bunches, plastic, rice huskAbstract

Used plastic in the form of polybags in the rehabilitation of plantation and agricultural land takes a very long time to be degraded naturally by sunlight (photodegradation) and soil microorganisms (biodegradation). One way to overcome this deficiency is to make bio polybags that function as nursery containers. This research aims to make biopolybags from empty fruit bunches (EFB) more environmentally friendly because they are easily decomposed into natural fertilizers for plants. The research was carried out from June to September 2021 at The Processing Technology Laboratory and Material Laboratory, LPP Polytechnic. Bio polybag is made in several stages, i.e. grinding, mixing of materials and adhesives, shaping, drying and mechanical testings. Mechanical tests carried out are compressive tests, tensile strength tests, and hardness tests, and to confirm the results, a density test was performed. Each mechanical property test was repeated three times. The samples represent each variation of the variables. The best bio polybag result is the bio polybag of EFB, which is reinforced by a 6 g rice husk filler with a tapioca adhesive of a measure of 20%. The highest test value obtained is: 1,495 kg.cm-2 for press strength value; 404,46 kgf.cm-2 (39,67 MPa) for tensile strength; and 63,99 HV for hardness value. The existence of this bio polybag is expected to replace the plastic that is difficult to degrade because it can decompose quickly, is more practical to be planted directly, and does not cause root damage during seedling.Downloads

References

Bachtiar, Ghulamahdi, M., Melati, M., Guntoro, D., & Sutandi, A. (2016). Kebutuhan Nitrogen Tanaman Kedelai Pada Tanah Mineral dan Mineral Bergambut Dengan Budi Daya Jenuh Air. Jurnal Penelitian Pertanian Tanaman Pangan, 35(3), 217–228.

Bakri, Gunawan, E., & Sanusi, D. (2006). Physical and Mechanical Properties of Sawdust- Cement Wood Composite. Perennial, 2(1), 38–41.

Bui, F., Lelang, M. A., & Taolin, R. I. C. O. (2016). Pengaruh Komposisi Media Tanam dan Ukuran Polybag Terhadap Pertumbuhan dan Hasil Tomat (Licopercicum escelentum Mill). Savana Cendana, 1(01), 1–7. https://doi.org/10.32938/sc.v1i01.1

Darwis, A. Z. A., Budianto, & Muditha, I. G. N. (2020). Penggunaan Berbagai Komposisi Media Tanam dan Konsetrasi Pupuk Organik Cair (POC) Terhadap Produksi Tanaman Sawi di Desa Mappesangka, Kec. Ponre, Kab. Bone, Provinsi Sulawesi Selatan. Bionature, 21(1), 31–36.

Effendi, Z. (2017). Perancangan Green Polybag dari Limbah Kelapa Sawit sebagai Media Pembibitan Pre Nursery Tanaman Kelapa Sawit (Elaeis guineensis Jacq). AGROSAMUDRA, Jurnal Penelitian, 4(2), 22–29.

Halim, M., Wahyudi, E., & Putra, I. A. (2019). Pemberian Pupuk NPK dan Kompos Tandan Kosong Kelapa Sawit pada Pertumbuhan Bibit Kelapa Sawit (Elaeis guineensis Jacq) di Pembibitan Awal. Agrinula : Jurnal Agroteknologi Dan Perkebunan, 2(1), 9–12. https://doi.org/10.36490/agri.v2i1.124

Jaya, J. D., Darmawan, M. I., Ilmannafian, A. G., & Sanjaya, L. (2019). Quality Green Polybag from Palm Oil Empty Fruit Bunch and Fiber Waste as Palm Oil Pre Nursery Media. Jurnal Teknologi Agro-Industri, 6(2), 127–140.

Manurung, B., Sjofjan, J., & Armaini. (2016). Aplikasi Abu Sekam Padi dan Kompos TKKS pada Padi Gogo (Oryza sativa L.) di Areal Gawangan Kelapa Sawit pada Lahan Gambut. JOM Faperta, 3(1), 1–15.

Nugroho, S. T. A., Akmalah, E., & Ainun, S. (2018). Pengembangan Indikator Waste (Sampah) pada Penerapan Konsep Green Campus di Itenas. RekaRacana: Jurnal Teknil Sipil, 4(1), 122–132. https://doi.org/10.26760/rekaracana.v4i1.122

Nurhilal, M. (2017). Karakteristik Papan Partikel Sekam Padi Variasi Campuran Dedak (Sekam Padi Giling) Dan Rasio Kompaksi. Proceeding Seminar Nasional Vokasi dan Teknologi (Semnasvoktek), 192–199.

Nursyamsi, & Tikupadang, H. (2014). Pengaruh Komposisi Biopotting terhadap Pertumbuhan Sengon Laut (Paraserianthes falcataria L. Nietsen) di Persemaian. Jurnal Penelitian Kehutanan Wallacea, 3(1), 65–73. https://doi.org/10.18330/jwallacea.2014.vol3iss1pp65-73

Palembangan, M. T., Parung, H., & Amiruddin, A. A. (2019). Characteristics Study Compressive Strength and Tensile Strength of PVA-ECC. Dynamic SainT, IV(1), 773–781.

Prakusya, H., Wicaksono, S. T., & Hidayat, I. P. (2019). Pengaruh Komposisi Filler Limbah Papan Semen Partikel. Jurnal Teknik Its, 8(2), 98–105.

Rifaldi, A., Hs, I., & Bahruddin. (2017). Sifat dan Morfologi Bioplastik Berbasis Pati Sagu dengan Penambahan Filler Clay dan Plasticizer Gliserol. Jom FTEKNIK, 4(1), 1–7.

Umam, M. K., Noerochim, L., & Wicaksono, S. T. (2019). Pengarun Komposisi Filler Limbah Cangkang Kerang dan Fiberglass terhadap Sifat Fisis dan Mekanik Komposit untuk Aplikasi Papan Partikel Semen. Jurnal Teknik ITS, 6(2), D118–D120.

Umrisu, M. L., Pingak, R. K., & Johannes, A. Z. (2018). Pengaruh Komposisi Sekam Padi Terhadap Parameter Fisis Briket Tempurung Kelapa. Jurnal Fisika : Fisika Sains Dan Aplikasinya, 3(1), 37–42. https://doi.org/10.35508/fisa.v3i1.592

Yoricya, G., Aisyah, S., Dalimunthe, P., Manurung, R., & Bangun, N. (2016). Hidrolisis Hasil Delignifikasi Tandan Kosong Kelapa Sawit dalam Sistem Cairan Ionik Choline Chloride. Jurnal Teknik Kimia USU, 5(1), 27–33.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Alviyer Saragih, Oktaviani, Widi Dwi Oktoria, Rina Ekawati, Lestari Hetalesi Saputri

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Authors who publish with Jurnal Agro Industri Perkebunan agree to the following terms:

Authors retain copyright and grant the Jurnal Agro Industri Perkebunan right of first publication with the work simultaneously licensed under a Creative Commons Attribution License (CC BY-SA 4.0) that allows others to share (copy and redistribute the material in any medium or format) and adapt (remix, transform, and build upon the material for any purpose, even commercially) with an acknowledgment of the work's authorship and initial publication in Jurnal Agro Industri Perkebunan.

Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in Jurnal Agro Industri Perkebunan. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.